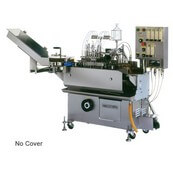

Are you looking for a pharmaceutical machinery manufacturer? Chin Yi is a leading pharmaceutical machinery manufacturer worldwide. We specialize in making high-performance and durable pharmaceutical machinery equipment to meet customer-specific demands. Welcome to contact us to get more pharmaceutical machinery information!